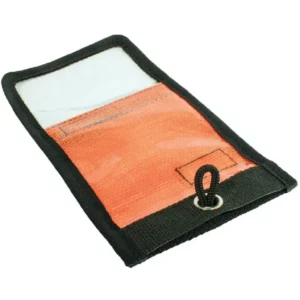

The Cobra MKII Retractable Lanyard is engineered for intense daily use, the Cobra is a heavy duty retractable tool lanyard featuring an ABS rubberised housing, internal moulded supports and high quality stainless steel components. It retrofits onto all belts and harness straps via a removable back bridge and houses a flexible PU coated stainless steel wire (Ø 1.9mm, 1.25m extended length). A swivel also prevents line-twist and connector roll-out.

The Cobra MKII + Easyreel option comes with an omnidirectional swivel system that increases range of motion. Two in-line swivels maintain alignment between the reel and tool to provide smooth action and reduced cable friction. Allows attachment to tool bags etc.

The Cobra MKII + Handrail Strap option comes with triple-lock velcro fastening, allows attachment to scaffolding, MEWPS, scissor lifts, handrails and plant. max tube Ø 50mm, straps overlap in opposite directions increasing strength of fastening.